The assembly and sealing processes of prismatic LFP cells are far more complex than they appear, involving three critical levels: cell-level electrode stacking and housing sealing, module-level thermal management and structural fixation, and system-level protection rating compliance and long-term reliability assurance. Each level presents unique technical challenges and solutions.

IP67 protection requirements, thermal runaway suppression, airtightness testing standards, and welding process control form a complete process system. Different applications have distinct requirements: consumer electronics prioritize compactness and cost control, energy storage systems focus on long-term stability, while electric vehicles balance weight reduction with safety considerations.

Table of Contents

Level 1: Cell-Level Assembly

Terminal Connections

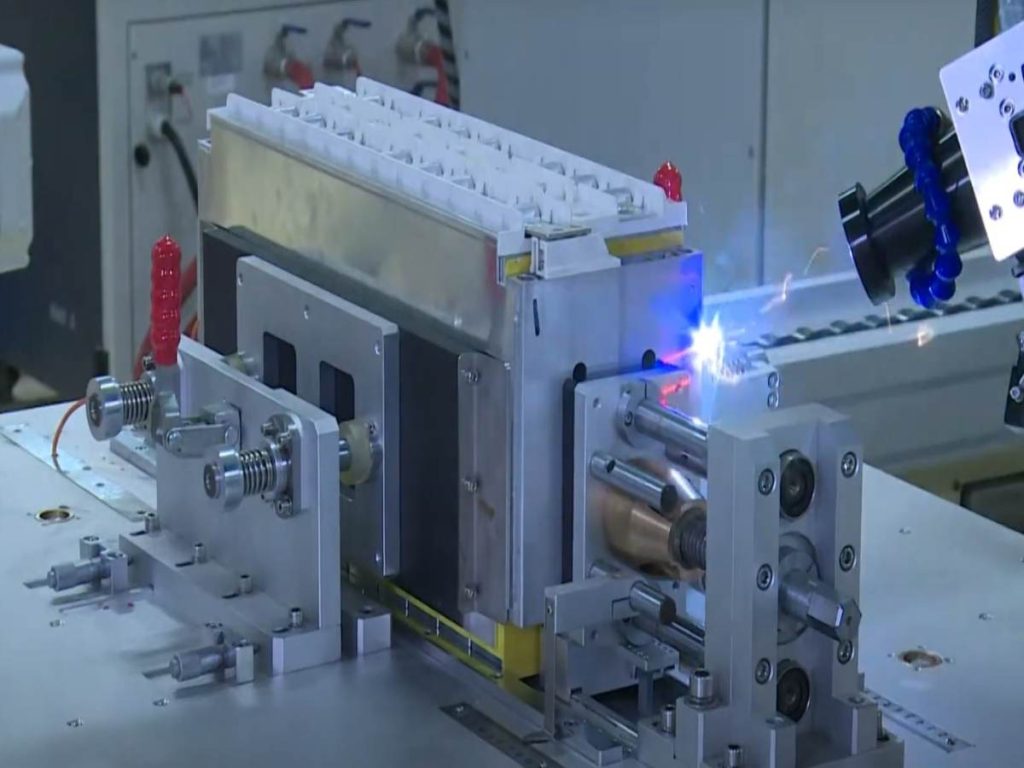

A bolted busbar lets you unbolt and swap a faulty prismatic LFP cell, so installers still like it for stationary energy-storage shelves where routine torque checks are easy. Laser-welded tabs occupy almost no space, give micro-ohm resistance, and slot into high-speed EV automation lines. Conductive adhesives reduce hardware costs and bond dissimilar metals, yet they cure slowly and can be more challenging to rework, so their joints tolerate less peel and impact than a weld or bolt.

Cell Arrangement

Lining cells up horizontally or vertically keeps airflow channels straight, making pack cooling models simpler to tune during fast-charge testing. Stacking the same prismatic LFP cell inside a compression frame adds more than 500 kg of clamping force, holding swelling in check and stiffening the module for crash loads. A bare-cell stack strips out module walls to save weight, but then the outer case must pick up all the structural, sealing, and fire-containment duties.

Level 2: Module-level Packaging

Standard Metal Frame Module

In a standard metal-frame module, each prismatic LFP cell stack sits inside an aluminum shell with an insulating liner. Compression plates clamp the stack to prevent swelling and maintain good electrode contact over extended periods. The finished module slides into a rack so technicians can wire multiple units quickly for commercial energy-storage rooms.

Hot-Swappable Module

Hot-swappable trays follow a 19-inch format that packages several cells, a small BMS, and quick-disconnect power and data plugs in one pull-out drawer. A technician can open a rack door, swap the drawer, and the system continues running, which keeps idle time close to zero.

Cell-to-Pack (CTP) Integration

CTP eliminates the module casing and bolts rows of prismatic LFP cells straight into the pack enclosure. This direct layout recovers roughly 15-50% of wasted volume, boosting energy density, but a failed cell now means opening the whole pack instead of sliding out a tray.

Level 3: System-Level Enclosure

Rack-Based Cabinets

In rack-level designs, multiple prismatic LFP modules are stacked into standardized 19-inch cabinets. The system requires precision in module alignment, vibration damping, and front-rear airflow sealing to ensure thermal consistency. Rubber gaskets or foam compression seals are applied around ventilation zones to prevent hot air recirculation. Cable glands and sealed connectors are used for power and communication lines, maintaining enclosure integrity while allowing modular expansion.

Containerized Energy Systems

At the grid scale, integrators mount hundreds of sealed battery modules into pre-engineered ISO containers. These containers act as a unified sealed housing, often equipped with industrial-grade insulation, multi-stage air filtration, and positive pressure ventilation to avoid dust and moisture ingress. The container’s structure incorporates welded joints and rubber-sealed access panels, ensuring IP54 or higher protection. All HVAC and fire suppression systems are factory-integrated, minimizing exposure during transport and installation.

Wall-Mounted All-in-One Units

For residential and light commercial use, wall-mount systems integrate prismatic cells, BMS, and inverter components into a compact sealed enclosure. These units feature double-layer casing with internal shock isolation and high ingress protection (IP65+), ensuring safe outdoor installation. Thermal pads and internal pressure relief valves are embedded to handle temperature and gas buildup, while daisy-chain expansion ports are shielded with rubber caps to preserve sealing during unused states.

EVE’s Prismatic LFP Cells: Scalable Power from 102Ah to 314Ah

EVE offers prismatic LiFePO4 cells at 3.2 V with capacities from 102 Ah (LF100LA) up to 314 Ah (MB31), and intermediate options such as LF105, LF150, LF168, LF230, LF280K-V3, and LF304 for flexible pack design. Their flat shape drops into rectangular stacks, keeps busbars short, and speeds up module assembly. Because every size keeps the same nominal voltage, EVE’s LiFePO4 battery cells scale smoothly from small mobility packs to large energy-storage racks.

Key Models Overview:

🔹 LF100LA – 102Ah

- Energy-dense and compact, perfect for portable power stations, AGVs (automated guided vehicles), and light mobility solutions.

- Long cycle life (typically 5000 cycles at 80% DOD).

🔹 LF105 – 105Ah

- Offering enhanced energy output with similar dimensions.

- Ideal for mid-size residential ESS (energy storage systems).

🔹 LF150 – 150Ah

- A solid option for solar energy storage and telecom backup systems.

- Balances size and capacity for modular cabinet integration.

🔹 LF230 – 230Ah

- One of EVE’s most popular models for commercial and engineering vehicles.

- Supports high current loads with excellent thermal stability.

🔹 LF280K-V3 – 280Ah

- A next-generation cell with enhanced cycle life (8000 cycles).

- Designed for large-scale ESS and off-grid systems where long-term reliability is critical.

- V3 enhancements improve consistency between cells, reducing pack balancing requirements.

🔹 LF304 – 304Ah

- Among the highest-capacity prismatic cells available in the standard form factor.

- Perfect for commercial vehicles, engineering machines, and shipment energy storage systems.

🔹 MB31 – 314Ah

- Flagship high-capacity model in EVE’s prismatic lineup.

- Used in containerized energy storage solutions (ESS), utility-scale batteries, and heavy-duty applications.

- Combines extreme capacity with robust safety mechanisms and structural durability.

Final Words

In conclusion, mastering the three-level assembly and sealing methodology for prismatic LFP cells requires a comprehensive understanding of cell-level precision, module-level integration, and system-level protection standards. Success depends on selecting appropriate processes for specific applications while maintaining strict quality control throughout each manufacturing stage to ensure optimal performance and reliability.