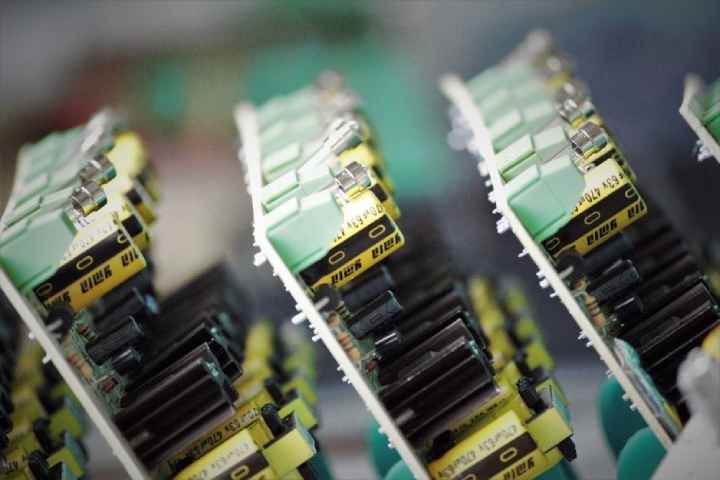

Why electronics engineers prefer PCB over wired circuits? They design these PCB circuits to store more wires in less space.

It is crucial to prepare PCB (Printed Circuit Board) with good components to ensure the circuit’s life and not create many complications in the circuit.

When experts start their work on different circuit boxes, they can also face some complications. These complications may occur due to several minor mistakes they repeatedly perform while preparing a PCB.

PCB components are complicated to create, but one must consider these 6 things while choosing PCB components.

Table of Contents

Decide the footprints of PCB.

Drawing the schematic phase, considering the footprints and land pattern, will provide several outputs of the layout phase. While preparing the footprints, remember to make several patterns that can allow the circuit to get connections according to the dimensions—select packing restrictions on the top and bottom parts of the PCB prepared.

Crucial components of PCB need to be recognized whenever it comes to preparing a long-lasting PCB. Polarized capacitors are something that can provide height clearance to the PCB.

While designing an initial PCB box, always consider preparing a rough outline with all the PCB’s crucial components. Then consider land patterns to solder the exact holes and shapes that are related to the circuit. While soldering, it requires proper thermal management because mechanical and thermal integrity makes the soldering better for a long-lasting PCB. If you manage the pads properly, you can get to access the PCB with other components.

Ensure good grounding services

Components like capacitors and ground planes need a perfect bypass option to resist the circuit operating complication. We recommend using adequate decoupling capacitors to reduce the rest of the circuits’ effect while using IC. These decoupling capacitors also bypass the power supply to the crucial part of the circuit.

According to the size of PCB, decoupling capacitors in the ground plane enhance that particular circuit’s performance.

While using IC’s to the circuit, make sure to create enough space to let the IC breathe with the circuit. This space is crucial to enhance the service of IC in the PCB because for soldering IC to the PCB, and several complications are there to solder it.

You can save a lot of time while soldering the IC to the PCB.

Find virtual parts footprints.

To check the virtual parts, running a bill of material (BOM) can help out to find the track of footprints. PCB components symbol allows you to understand better footprints, and remembering these symbols is also not that much more complicated.

Generating a BOM will allow you to prepare the blueprint of a complete PCB design. It will help you analyze what changes are there to fix and how it can give perfect outcomes. The power and ground signals should be considered the virtual parts that the virtual environment has handled but not the footprints.

After considering the final assessment, the main parts from the virtual parts can get the footprints. These virtual parts can be replaced with the parts with the footprints, and it will give a perfect result of a PCB. The chances of errors in the circuit box become negligible when it comes to managing the virtual parts with the footprints.

Also Read: KEYS TO PROTECT YOUR ROUTER: AVOID MALWARE AND DETECT IF SOMEONE STEALS YOUR WIFI

Ensure to have a complete set of BOM data.

While performing BOM management, always remember to prepare the data smartly and adequately. It will help you analyze several things, which can give multiple outcomes of the PCB. It will create a better engagement with the circuit if an adequate bill of material data is available. The BOM is a list that consists of all the crucial electric components that can help in preparing several PCBs. Bill of materials provides enough details about the outcomes of a certain component on the PCB when the expert is placing these components on the board.

Always make sure that the data of BOM is complete before working on PCB management. While using the BOM, several components get different results, so with the accurate use of BOM, the PCB component list will get the management’s perfect order. The adequate BOM data is sufficient to make the PCB works faster than it can do.

Ensure to analyze the thickness of the board

The thickness of the board without any component is something that shows the height of that particular board. If the board’s thickness is good, then several components can be fixed in the PCB, and it will balance the transfer of heat in that box. This means thickness will not only provide space to fix the components, but it will also manage the temperature of that particular circuit.

The thick board allows the system to manage more complex circuits, and the ability to route signals also get a hike with a perfect height PCB device. This is suitable for the PCB functionality with the perfect management of complex circuits and temperature at the same time.

Increased PCB boards can manage multilayer PCB systems without getting any compilations to manage that particular circuit and manage layered circuits. It allows a thick PCB to work accurately, even in odd conditions.

Analyze the spare gates

To prevent the signals from floating due to inputs, spare gates hold the signal to the circuit. After completing the PCB, make sure to review every spare gate to connect the floating wires to the circuit to make it complete.

Several cases are there where the IC doesn’t work when the circuit is floating on the PCB, and it also creates several issues with the circuit. The circuit stops working to the saturation level and affects the performance of the device. Grouping these wirings help the experts to analyze the spare gates and prepare a PCB with better performance. If the analysis of spare gates is perfect, then the PCB’s performance will get a boost.

Simulation models do not connect the IC sections to reduce the negative impacts of PCB design.

Also Read: How To Protect Your Devices From Computer Viruses